Industrie 4.0 & BaSys 4.2

Using AI methods to optimize production processes

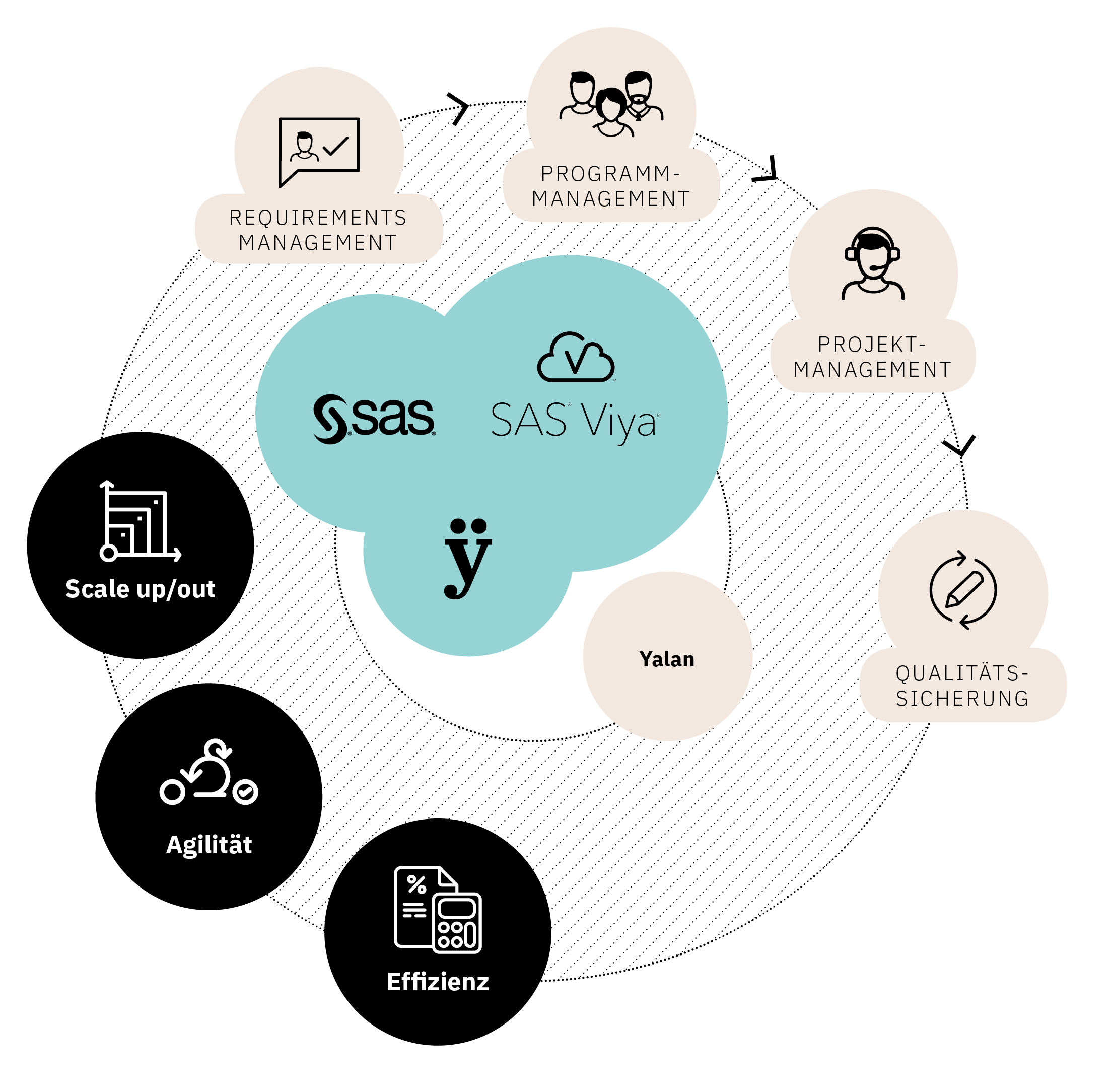

Companies that want to be ready for industrie 4.0 can count on our expertise: We support you with AI methods and intelligently integrate the knowledge of your employees and the diverse machine data into your processes - for an optimal production flow.

In Industrie 4.0, production processes interlock with modern information and communication technology: people, machines, plants, logistics and products communicate and cooperate directly with each other - via intelligent and digitally networked systems. Passive objects are equipped with microcontrollers, communication systems, identifiers as well as sensors and actuators, making mass data available to industrial companies. They are a valuable basis for developing standardized and individualized services. The prerequisite: companies can use this data.

As a partner of the BaSys Initiative of the German Federal Government and experienced service provider in the field of Smart Data, Advanced Analytics and AI, we support you in identifying, planning and implementing your Industrie 4.0 requirements. This is because we know the standards - such as the BaSys 4.0 middleware for production systems - and cooperate with specialized network partners such as the German Research Center for Artificial Intelligence (DFKI), Fraunhofer IESE and companies in the automation sector. Our specialty: Using artificial intelligence, which uses algorithms of machine learning and deep learning, to recognize valuable information in large, unstructured data sets.

A look into practice: Find out here how we integrate the speech analytics of VDPP into the messaging platform Treema within the framework of the industrie 4.0 funding project Akzent4BaSys. Employees in the production area can identify and resolve AI-supported problems in production processes faster.

We analyse the communication content and generate decisive added value.

It is important that the platform used is open enough to allow us to technically connect our speech analytics and thus our VDPP platform. Of course, it must also comply with the data governance and security requirements of GS Kunststofftechnik. The interaction platform will ultimately provide video telephony, embed machine data in a visualized form (e.g. a diagram showing the course of oil pressure) and automatically send messages to ticket systems and the MES as well as to maintenance staff, shift supervisors and production managers.

Our technology comprehensively evaluates text and speech and can be trained on the technical vocabulary of GS Kunststofftechnik - in the sense of comprehensive knowledge management. The employee himself controls which information he needs. If desired, he can "switch on" the language analysis into the communication. At the right moment, it then gives a hint that ensures that the machine will not only be running again in two days, but in two hours.

Industrie 4.0: Förderprojekt Akzent4BaSys

Mensch und Maschine sprechen eine Sprache – das könnte bald Realität sein bei GS Kunststofftechnik. Kommt es zu Störungen in der Produktion, analysiert unsere NLP-Technologie das gesprochene und geschriebene Wort der Werksmitarbeiter und liefert automatisiert Lösungen.

|

Download |

FlyerVDPP - Services and Platform for Smart Data & Knowledge Management |

You want to know more? We look forward to hearing from you.

Among other things, he takes care of the algorithms and the core of NLP. As part of the implementation team of the VDPP platform, he and his colleagues have the task of technically implementing the methods and goals, developing new methods and implementing them in the platform.

He studied architecture and philosophy and learned SAS at the Heidelberg University Computer Center. He financed his studies with an IT job at a young Heidelberg IT consultancy. After a few years there he took over the responsibility for several clients in the financial sector. Then he got the offer to spin off the business unit into his own company - the starting point of Kybeidos. There is one thing he appreciates most about his work: getting direct feedback from clients at the end of the day. And to see that you actually create business value and added value.